THE ZEFSCI BLOG

Preventative LCMS Maintenance: 3 Practical Care Tips for Labs

Routine preventative maintenance and system upkeep is essential for maintaining and extending the life of your sensitive LCMS equipment. In this blog, we’ll discuss the importance of scheduling preventative maintenance and how to better care for your LCMS systems.

LCMS preventative maintenance is essential to keeping lab operations moving. The problem is too many laboratories – especially smaller and academic laboratories – neglect to schedule preventative maintenance for their LCMS equipment.

Quite often, academic labs or smaller companies may not have the budget, staff or service plan to coordinate routine preventative maintenance.

However, regardless of the reasons for neglecting preventative maintenance, every lab should make sure LCMS instruments are routinely serviced. Here’s why.

The Importance of Regularly Scheduled Preventative Maintenance

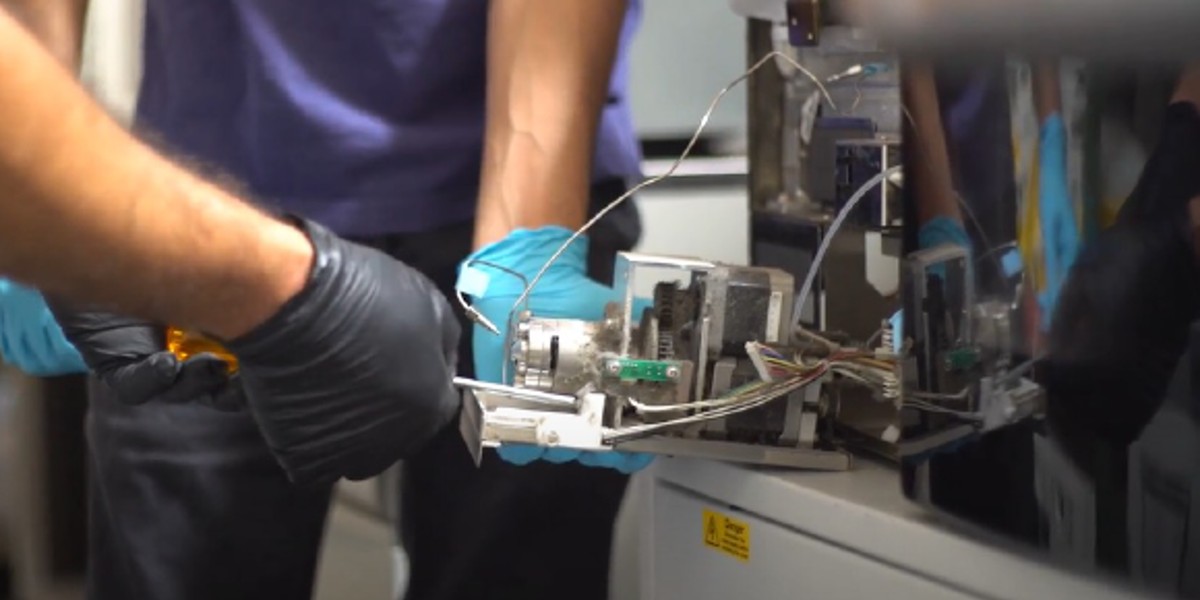

LCMS instruments are highly sensitive, containing many finely tuned parts that run under extreme conditions.

Many of those parts are consumable, meaning they have a certain lifespan where they work optimally. Once that lifespan is up, you run the risk of them breaking down and potentially causing bigger issues in the system.

There are also fluids running through the instrument constantly. Those fluids need to be changed or topped off regularly to prevent parts from seizing up.

For example, vacuum pumps used by the mass spectrometer may use oil. The level and color of this oil should be monitored, and oil added and changed as required by the manufacturer. If that oil runs out or gets excessively dirty, the pump seizes. So, what should have been a routine oil change can become a full pump replacement that can cost thousands of dollars.

As you can see, routine servicing and maintenance plans can help you stay ahead of catastrophic repairs. Getting an experienced engineer on site to look at your LCMS systems and replace consumable parts before they fail helps you fix problems before they occur.

That leads to greater cost savings and more up-time for your instruments.

How Does Preventative Maintenance Affect the Accuracy of Your LCMS Systems?

If your systems aren’t routinely maintained, it can start to affect your data. Most likely, you’ll notice a decrease in the sensitivity of the mass spectrometer. On the LC, you could start to see retention time or resolution issues, or lose sensitivity in the optical detectors.

How Often Should You Have Your LCMS Instruments Serviced?

In most cases, when we talk about preventative maintenance, we’re talking about an annual service from an experienced LCMS engineer.

If your instruments run particularly dirty samples, it could be wise to have maintenance done twice a year.

Regardless, it’s always valuable to have an experienced engineer inspect the LCMS to check the status of wear parts and the systems as a whole. If nobody is checking, then issues can go unnoticed until it’s too late.

Having your LCMS systems maintained by professionals is critical, but there are steps your lab can take to troubleshoot if problems arise.

3 Practical LCMS Care Tips for Labs

#1. Set Up a Cleaning Procedure

The first thing you can do is make sure your lab and your instruments are clean. Contamination can interfere with your LCMS system and accelerate the deterioration of critical parts.

As a result, it’s imperative that your lab have cleaning procedures in place, so that your instruments aren’t neglected.

#2. Routinely Change Your Mobile Phase

The mobile phase should be changed weekly. It should never be topped off in the old bottle. It must be prepared fresh in a new or clean bottle and the whole bottle needs to be replaced.

The reason being mobile phase that sits on the system too long can yield bad data. On top of that, if your mobile phase is particularly harsh, it can wear away at the wetted surfaces in your LC, causing corrosion and leakage that can ruin other critical parts.

#3. Refer to the Manufacturer’s Recommendations

LCMS instruments are complex, highly sensitive pieces of equipment, and each manufacturer has slight differences. It’s important that everyone in your lab working on these instruments is at least familiar with the manufacturer’s recommendations for routine maintenance.

Conclusion – Schedule Preventative Maintenance

At the end of the day, if you don’t schedule maintenance for your LCMS systems, they’ll schedule maintenance for you. Neglecting preventative maintenance on your LCMS systems can lead to costly repairs in the future.

LCMS instruments have parts that are not designed to last forever. Put in the time and investment to schedule routine maintenance. On top of that, make sure everyone in your lab who works on LCMS systems can properly operate and clean them at a surface level. When you do, your lab will run more efficiently, get more accurate data and most likely save money in the long run.

Looking to schedule preventative maintenance for your LCMS equipment? Get in touch with ZefSci to see how LCMS servicing should always be.